Had a quarry manager ask me last month, "Kevin, I know you sell boom systems, but what if a boom isn't right for us? What else should we be looking at?"

Honest question deserves an honest answer. Truth is, pedestal booms aren't the only game in town. There are plenty of other ways to break rock, and some might be better for your specific situation.

Let me walk you through the real alternatives - what works, what doesn't, and when you'd choose one over the other.

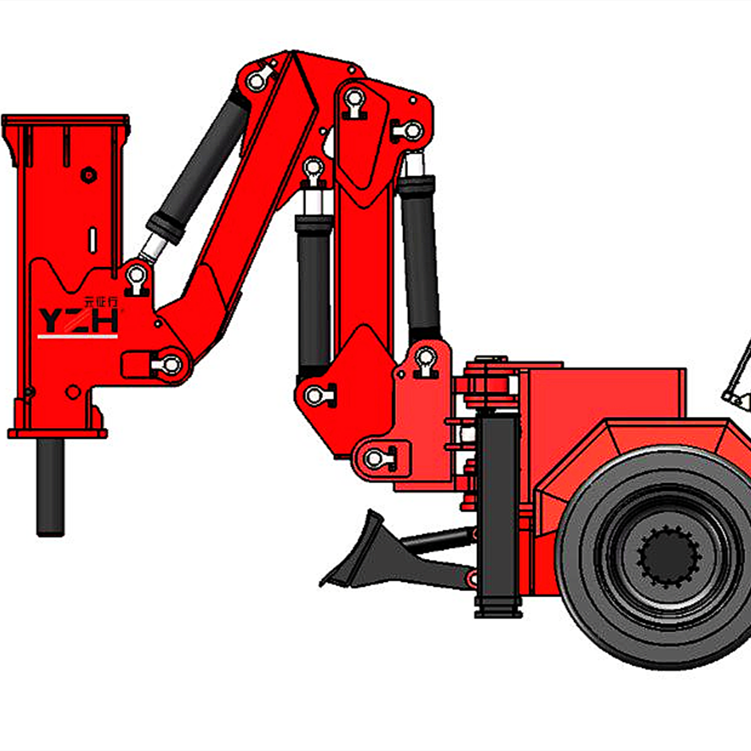

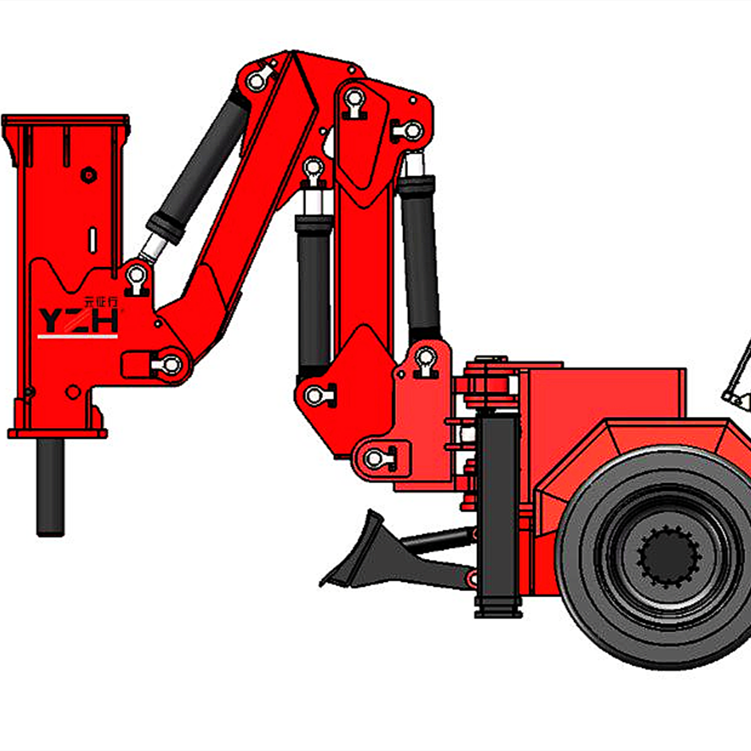

Mobile Hydraulic Breakers: The Flexible Option

This is probably what most people think of first when they need to break something.

How They Work

Excavator-mounted hydraulic hammers. Drive up, position, break stuff, move on. Simple concept that's been around forever.

Where They Shine

Mobile units are great when you need breaking capability in multiple locations. Quarry with several working faces? Construction site with demo work scattered around? Mobile makes sense.

Flexibility is the big advantage. One machine can handle breaking needs across a large area. No fixed installation, no permanent commitment to one spot.

The Reality Check

But here's what the sales brochures don't tell you - mobile units are slow to deploy. Drive time, positioning, outrigger setup. By the time you're ready to break, a fixed boom would've already finished the job.

And precision? Forget about it. Mobile units are great for general demolition but terrible for precise work around crushers or in tight spaces.

Had a cement plant try mobile units for primary crusher feed control. Took 15 minutes to position the machine every time they had an oversized chunk. Boom system would've handled it in 30 seconds.

When to Choose Mobile

Multiple breaking locations

Occasional breaking needs

General demolition work

Budget constraints (lower initial cost)

Drop Balls: Old School Simple

Some operations still use drop balls - literally dropping heavy steel balls on material to break it.

The Appeal

Simple, cheap, no hydraulics or electronics to maintain. Just a crane, a cable, and a really heavy ball.

The Problems

Limited effectiveness on tough material. No precision - you're basically playing rock roulette. Safety concerns with overhead lifting. And it's slow as hell.

Saw this at an old aggregate operation. They'd spend half an hour positioning material under the drop ball, then drop it maybe 20 times to break one piece. Meanwhile, production was stopped.

Reality

Drop balls are mostly obsolete except for very specific applications. If someone's suggesting drop balls for your operation, they're probably not thinking creatively enough about solutions.

Explosives: The Nuclear Option

When you absolutely, positively need to break everything overnight.

The Power

Nothing breaks rock like explosives. Massive boulders, solid rock faces, whatever - explosives will reduce it to manageable size.

The Complications

But man, the complications. Permits, licensed blasters, evacuation zones, vibration monitoring, flyrock control. And forget about using explosives near active equipment or in populated areas.

Worked with a quarry that had a massive boulder problem in their pit. Explosives were the only realistic option, but the permitting and safety requirements took six months to sort out.

When It Makes Sense

Massive material that nothing else can handle

Remote locations away from equipment and people

Planned operations where you can shut everything down

Material that's too hard for mechanical breaking

When It Doesn't

Hydraulic Splitters: The Quiet Option

These use hydraulic pressure to split rock along natural fractures.

How They Work

Drill holes in the rock, insert splitter wedges, apply hydraulic pressure. Rock splits along the line of least resistance.

Advantages

Quiet operation - great for urban areas or noise-sensitive locations. No vibration, no flyrock, very controlled breaking.

Limitations

Slow as molasses. Only works on material with natural fractures. Limited to relatively small pieces. And you need access to drill holes first.

Had a demolition contractor use these for breaking concrete in a hospital renovation. Worked great because noise was a major concern, but it took forever.

Best Applications

Thermal Methods: The Specialty Play

Flame cutting, plasma cutting, thermal lances - using heat to break or cut material.

Where They Work

Mostly for metal cutting rather than rock breaking. Steel structures, reinforced concrete with heavy rebar, metal components that need precise cutting.

Limitations

Fire hazards, toxic fumes, specialized operators required. Not practical for most rock breaking applications.

Niche Applications

Demolition of steel structures

Cutting heavy reinforcement in concrete

Salvage operations

Specialized industrial applications

Chemical Expansion: The Patient Approach

Chemical compounds that expand when mixed with water, creating pressure to crack rock.

The Process

Drill holes, pour in the chemical compound, add water, wait. Expansion pressure cracks the rock over several hours.

Pros and Cons

Quiet, no vibration, no special permits. But incredibly slow - we're talking hours or days for results. And only works on certain rock types.

Limited Use

Mostly used in decorative stone quarries where preserving the rock structure is critical. Not practical for most industrial applications.

How to Actually Choose

Here's how I help customers think through their options:

Speed Requirements

Need immediate results? Booms or mobile breakers. Can wait? Consider splitters or chemical methods.

Location Flexibility

Multiple breaking locations favor mobile equipment. Concentrated needs favor fixed installations.

Precision Needs

Precise breaking around equipment? Booms win. General demolition? Mobile units work fine.

Safety Constraints

Tight safety requirements eliminate explosives and some thermal methods. Remote operation favors booms.

Noise Restrictions

Urban or noise-sensitive areas favor hydraulic splitters or chemical methods.

Material Characteristics

Hard, massive rock might need explosives. Fractured rock works with splitters. Regular-sized material suits mechanical methods.

Budget Reality

High initial cost but low operating cost? Fixed installations. Lower initial cost but higher operating cost? Mobile equipment.

The Honest Assessment

Most operations end up choosing between pedestal booms and mobile hydraulic breakers. Everything else is specialty applications.

Booms Win When:

Mobile Wins When:

Everything Else:

Explosives for massive, impossible material

Splitters for noise-sensitive precision work

Thermal for metal cutting

Chemical for decorative stone work

Real Talk

Don't get caught up in exotic solutions. Most rock breaking comes down to mechanical impact - either from a fixed boom or mobile equipment.

The fancy alternatives have their place, but they're usually specialty solutions for specific problems. Start with the basics and only consider alternatives when the basics don't work.

And here's something nobody talks about - you don't have to choose just one method. Lots of operations use multiple approaches. Boom for primary crusher feed control, mobile equipment for general pit work, explosives for the occasional massive boulder.

The key is matching the method to the specific job, not trying to find one solution that does everything.

Trying to figure out the best breaking method for your operation? Let's talk through what you're actually dealing with. Every situation's different, and the right solution depends on your specific requirements.