In the high-stakes worlds of mining, quarrying, and construction, equipment downtime is the enemy of profitability. At the heart of these operations lies the rock breaker and crushing ecosystem—machinery designed to reduce massive geological formations into manageable, usable aggregates.

Whether you are managing a primary crushing station in a mine or a concrete recycling plant, understanding the mechanics of your equipment is crucial. This guide aims to demystify the working principles of various rock crushers, help you select the right machinery, and—most importantly—demonstrate how to maximize production efficiency using advanced solutions like Pedestal Boom Systems to handle oversized material.

1. Basic Concepts of Rock Breaking

What is a Rock Breaker?

In the industry, the term "rock breaker" often refers to two distinct categories of equipment:

Crushers: Large machines (like Jaw or Cone crushers) that process continuous streams of material.

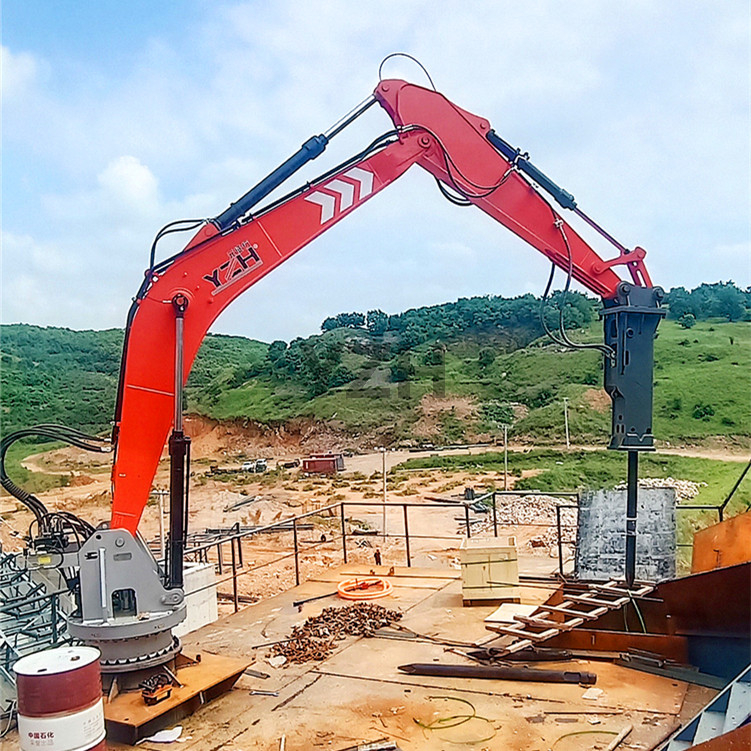

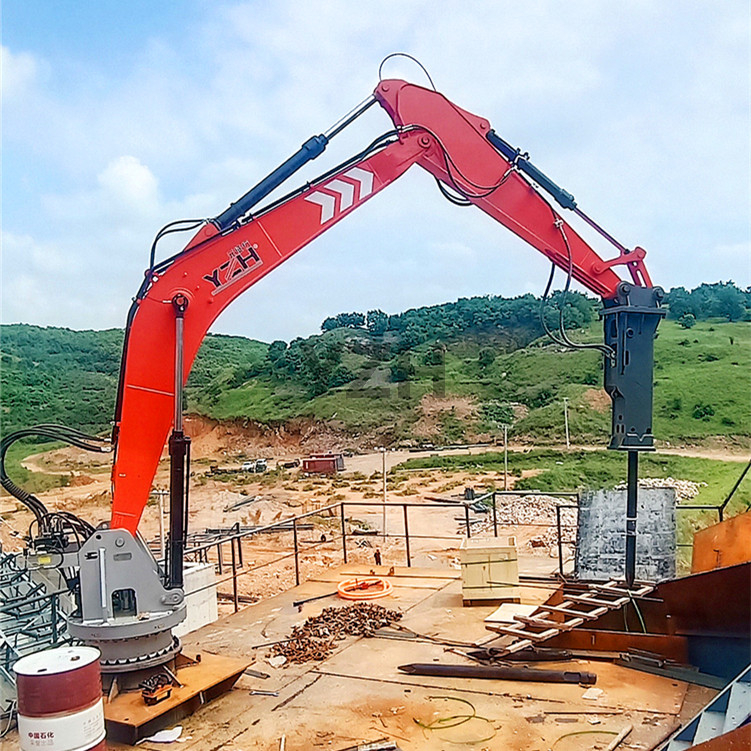

Hydraulic Breakers (Pedestal Booms): Stationary arms equipped with hydraulic hammers, mounted above crushers to break oversized rocks that cause jams.

Main Types of Crushers

To build an efficient production line, one must understand the primary tools available:

Jaw Crushers: The "workhorse" for primary crushing.

Impact Crushers: Ideal for softer rock and shaping.

Cone Crushers: Precision machines for secondary or tertiary crushing.

Hammer/Impact Breakers: Used for specific industrial applications.

2. Working Principles of Rock Crushers

Understanding how rock is broken helps in selecting the right tool for the geology you are facing.

2.1 Jaw Crusher

The Principle: Mimics a chewing motion. Material is compressed between a fixed jaw plate and a moving jaw plate (driven by an eccentric shaft).

Pros & Cons: Excellent for hard, abrasive rock. However, they are prone to "bridging" (blockages) when oversized rocks enter the chamber.

Optimization: This is where a Pedestal Boom System is essential to clear jams safely without stopping the plant.

2.2 Impact Crusher

The Principle: Uses kinetic energy. Rapidly spinning blow bars strike the rock, throwing it against impact plates (aprons).

Pros & Cons: Produces a cubical product shape (great for asphalt/concrete). High wear cost on abrasive materials.

2.3 Cone Crusher

The Principle: A mantle rotates eccentrically within a concave bowl. Rock is squeezed and crushed as the gap closes.

Pros & Cons: High efficiency for secondary crushing; produces uniform output. Not suitable for large, primary feed sizes.

2.4 Hammer Crusher

The Principle: High-speed hammers impact the material directly.

Pros & Cons: High reduction ratio (big rock to sand in one step), but maintenance costs are high if the rock is abrasive.

3. Industry Applications

3.1 Mining Industry

In open-pit and underground mines, reliability is paramount.

3.2 Construction & Aggregates

Application: Producing gravel, sand, and road base.

Focus: Shape and consistency of the rock are key for high-quality concrete production.

3.3 Demolition & Recycling

4. Choosing the Right Rock Breaker Solution

Selecting the correct equipment depends on three critical factors:

Factor | Consideration |

Material Hardness | Abrasive granite requires Jaw/Cone crushers; Limestone suits Impactors. |

Feed Size | Ensure the intake opening is larger than your largest blasted rock. |

Safety & Continuity | Do you have a plan for blockages? If a rock is too big, you need a stationary breaker boom. |

Brand Reputation: Always choose suppliers with a track record of durability and parts availability.

5. Solutions for Improving Production Efficiency

Efficiency isn't just about speed; it's about reducing downtime.

The Hidden Cost of Jams

When a primary crusher gets blocked by an oversized rock, the entire mine stops. Sending a human into the crusher with a handheld tool is dangerous and slow.

The Pedestal Boom Solution

Installing a Pedestal Boom System is the industry standard for efficiency.

Zero Downtime: The operator breaks the oversized rock remotely from a control room.

Safety: No personnel ever enter the crushing chamber.

Throughput: Maintains a consistent flow of material.

6. Service and Technical Support

Buying heavy machinery is a partnership, not a one-time transaction.

After-Sales Support: Ensure your supplier offers installation guidance, hydraulic tuning, and spare parts availability.

Training: Proper operator training on how to use breaker booms extends the life of both the boom and the crusher.

Conclusion

Rock breaking is a science that balances force, geology, and mechanical engineering. Whether you are utilizing a jaw crusher for granite or an impactor for limestone, the goal remains the same: safe, efficient production.

To truly optimize your operation, you must look beyond just the crusher itself and consider the ancillary equipment that keeps it running. Integrating a Pedestal Boom System is often the highest ROI investment a site can make to ensure safety and eliminate bottlenecks.

Ready to optimize your crushing circuit? Explore our range of Pedestal Boom Systems or contact our engineering team for a custom assessment.

FAQ (Frequently Asked Questions)

Q1: What is the main difference between a Jaw Crusher and a Cone Crusher?

A: A Jaw Crusher is typically used for the primary stage (breaking big rocks into medium ones), while a Cone Crusher is used for secondary or tertiary stages (making medium rocks into small stones or sand).

Q2: How do I maintain a rock breaker boom?

A: Regular greasing of the chisel, checking hydraulic pressure, and inspecting hoses for leaks are daily essentials. An automatic lubrication system is highly recommended.

Q3: Why is my crusher constantly jamming?

A: This usually happens if the feed size is too large or the feed rate is uncontrolled. Installing a Pedestal Boom System at the feeder is the most effective way to manage these jams instantly.

Q4: Can a pedestal boom be retrofitted to an existing plant?

A: Yes, most pedestal booms are designed to be mounted on existing steel structures or concrete foundations near the crusher intake.