I was standing in a control room in Montana last month, watching an operator clear a crusher jam from 200 feet away. Coffee in one hand, joystick in the other. The whole thing took maybe three minutes.

Two years ago, that same jam would have meant suiting up three guys, shutting down the plant for two hours, and sending them into a 30-foot crusher chamber with pry bars and sledgehammers.

That's the difference boom systems make. It's not just about clearing jams - it's about solving problems that other methods simply can't handle.

The Precision Problem

Manual jam clearing is basically controlled chaos. You send guys in with whatever tools fit through the access doors, and they beat on stuff until it moves.

Sometimes it works great. Sometimes it doesn't work at all. And you never really know which it's going to be until you're already committed.

The Reality of Manual Methods

I've watched crews spend six hours trying to clear a jam that a boom system would handle in fifteen minutes. Not because they weren't skilled - they were good operators. But they were working blind, in cramped spaces, with limited tools.

You can't get a 20-foot pry bar into most crusher chambers. You can't position yourself for optimal leverage. You can't see what you're doing half the time.

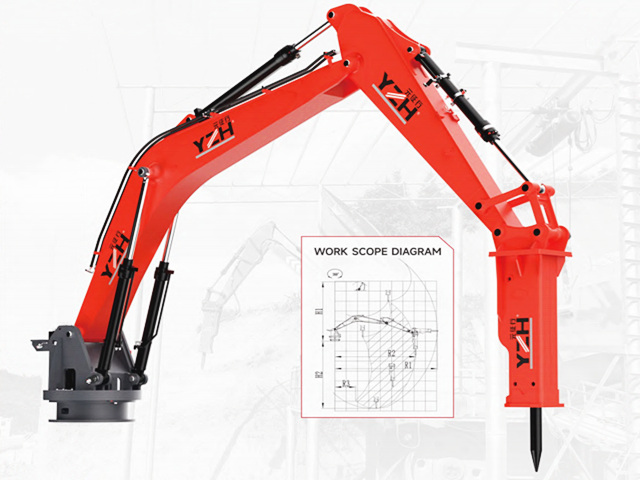

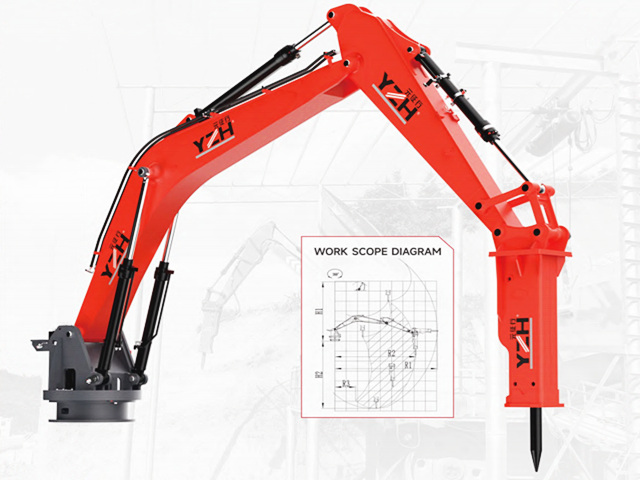

With a boom system, you position the hammer exactly where you need it. Every time. You can see what you're hitting, adjust your angle, apply force precisely where it's most effective.

Repeatability Changes Everything

Manual methods are different every time. Different crew, different approach, different results.

Boom systems are consistent. Same positioning, same force application, same technique. When you find what works, you can repeat it exactly.

I worked with a quarry that had one particular jam pattern that always gave them trouble. Took their crew 4-5 hours to clear manually, and sometimes they'd damage crusher liners in the process.

With the boom system, they developed a specific sequence - three hits in precise locations, specific angles, controlled force. Now that jam pattern clears in 20 minutes, every time.

The Safety Reality

Let's be honest - manual jam clearing is dangerous as hell. You're putting people in confined spaces with unstable material overhead, limited escape routes, and heavy machinery all around.

Elimination vs. Mitigation

Most safety approaches try to make dangerous work safer. Better procedures, more training, improved equipment.

Boom systems eliminate the danger entirely. No people in the crusher chamber means no exposure to crushing hazards, falling material, or equipment failures.

I remember a gyratory crusher accident a few years back. Material shifted while operators were in the chamber. One guy got pinned, took hours to extract him. He survived, but just barely.

With a boom system, that accident never happens. The operator is in a control room or at a remote station, completely out of harm's way.

The Psychological Factor

There's something else about boom systems that people don't talk about much - they change how operators think about jam clearing.

When jam clearing is dangerous, operators tend to rush. Get in, get it done, get out. That leads to shortcuts and mistakes.

When you're operating remotely, you can take your time. Think through the approach. Try different angles. Be methodical.

Better decisions, better results, safer outcomes.

The Availability Advantage

Manual jam clearing happens on maintenance schedules. Day shift, maybe swing shift if you're lucky. Nights and weekends? You're probably waiting until Monday morning.

24/7 Operations

Boom systems don't care what time it is. Jam at 2 AM on Sunday? Clear it immediately and keep running.

I worked with a cement plant that runs continuous operations. Before their boom system, weekend jams meant shutting down until Monday morning. Every weekend jam cost them about $200,000 in lost production and restart costs.

Now they clear jams immediately, any time of day or night. The boom system paid for itself in about eight months, just from improved availability.

Crew Independence

Manual clearing requires specific skills and experience. Not everyone can safely clear crusher jams.

Boom systems can be operated by anyone with basic training. Day shift, night shift, weekends - doesn't matter who's on duty.

Weather Independence

Ever tried to clear a crusher jam in a blizzard? Or during a thunderstorm? Manual methods get shut down by weather.

Boom systems work regardless of conditions. Enclosed operator stations, remote operation capability - weather doesn't stop production.

The Wear and Tear Factor

This one surprises people. Boom systems actually reduce crusher wear compared to manual methods.

Controlled Force Application

Manual clearing often involves beating on stuff with whatever tools you can get in there. Sledgehammers, pry bars, whatever works. It's effective, but it's hard on equipment.

Boom systems apply controlled, precise force. You can break material without damaging crusher components.

Strategic Breaking

With manual methods, you often have to break material wherever you can reach it. Not necessarily the best place, just the accessible place.

Boom systems let you position the hammer optimally. Break material at stress points, use leverage effectively, minimize the force required.

Reduced Secondary Damage

Manual clearing sometimes creates secondary problems. Damaged liners, bent components, disturbed settings.

Boom systems are more precise, less likely to cause collateral damage.

I worked with an operation that was replacing crusher liners every six months because of manual clearing damage. After installing a boom system, liner life doubled.

The Integration Game

Modern boom systems don't just clear jams - they integrate with plant control systems to prevent problems before they happen.

Predictive Capabilities

Advanced systems monitor material flow, power consumption, vibration patterns. They can identify developing jams before they become full blockages.

Automated Response

Some installations have boom systems that respond automatically to certain conditions. Material flow drops below threshold? Boom system activates automatically to clear developing restrictions.

Data Collection

Boom systems collect data on jam patterns, clearing effectiveness, equipment performance. That data helps optimize crusher settings and prevent future problems.

Remote Monitoring

Modern systems can be monitored and controlled remotely. Operators don't even need to be on site.

I know operations where boom systems are controlled from central dispatch centers hundreds of miles away.

What Other Methods Miss

Every alternative to boom systems has limitations that boom systems overcome.

Vibration Systems

Crusher vibration systems can help with some material flow issues, but they can't handle major jams. And they're hard on equipment.

Improved Feed Control

Better material handling reduces jam frequency, but it doesn't eliminate jams entirely. You still need a way to clear them when they happen.

Manual Tools

Better manual tools make clearing easier, but they don't solve the fundamental problems of access, positioning, and safety.

Crusher Modifications

Chamber modifications can reduce jam frequency, but they often compromise crushing efficiency or capacity.

The Operational Reality

Here's what boom systems really change in day-to-day operations:

Shift Handoffs

No more "we've got a jam, next shift will have to deal with it." Jams get cleared immediately, regardless of timing.

Production Planning

More predictable operations. Less unplanned downtime, more consistent throughput.

Maintenance Scheduling

Planned maintenance instead of emergency repairs. Better equipment utilization, lower overall costs.

Operator Morale

Nobody likes dangerous, difficult work. Boom systems eliminate the worst parts of crusher operation.

The Bottom Line

Boom systems solve problems that other methods simply can't address effectively.

Precision positioning that manual methods can't match. Complete elimination of human exposure to crushing hazards. Consistent, repeatable results. 24/7 availability regardless of crew schedules or weather conditions.

These aren't just incremental improvements - they're fundamental changes in how crusher operations work.

The question isn't whether boom systems are better than alternatives. In the right applications, there really aren't viable alternatives.

The question is whether your operation has the problems that boom systems solve. If you do, boom systems aren't just helpful - they're essential.

Dealing with operational challenges that seem impossible to solve? Sometimes the solution isn't improving existing methods - it's changing the game entirely.