| Availability: | |

|---|---|

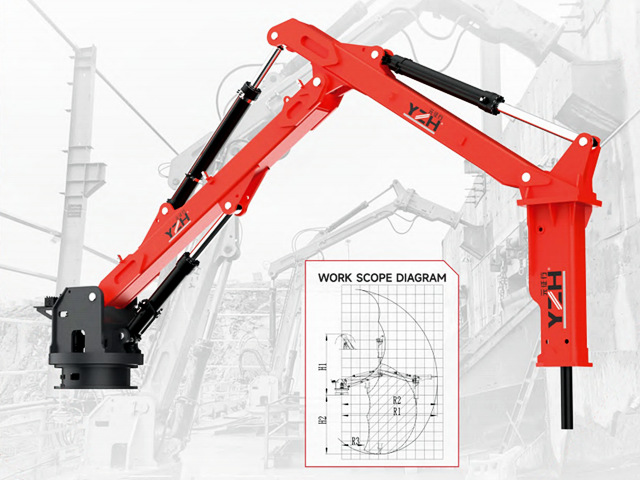

BH Series

YZH

Product Description

Pedestal Boom Rockbreaker System – Engineered for Precision, Power, and Productivity

BH series pedestal boom rockbreaker system includes: BHA300, BHA400, BHB350, BHB450, BHB500, BHB600, BHC500, BHC550, BHC630, BHD600, BHD650, BHD670, BHD750

Power of hydraulic power unit ranges: 18kw, 22kw, 30kw, 37kw, 45kw, 55kw, 75kw, 90kw

Weight ranges: 1912kg-7882kg

Vertical reach: 1610mm-8100mm

Rotation angle: 360°

OEM/ODM: Yes

Hammer rod tool diameter: 75mm-155mm

Operating temperature -45°C to +75°C

Mounting options: Floor mount, Crusher mount, Shock-absorbing base, Bridge tower mount, Rail trolley mount

All systems can be tailored to site-specific conditions including high altitude, corrosive, or explosive environments.

Pedestal boom rockbreaker system is a rugged, purpose-built hydraulic boom assembly mounted on a fixed pedestal, designed to facilitate the efficient breaking of oversize rocks and ore at grizzlies, crushers, hoppers, and draw points. It is an indispensable solution for improving material flow and reducing downtime in mining, quarrying, and aggregate processing operations.

Core Components & Configuration

1. Hydraulic Boom Assembly

Constructed from high-strength, wear-resistant steel for durability in extreme environments.

Comprises multiple sections (main boom, intermediate boom, and jib stick)

Configurable in multiple geometries (e.g., single boom, double boom, articulated boom) to suit various reach and breaking requirements.

Boom lengths range from 2 meters to over 10 meters, depending on model and application.

2. Hydraulic Rock Breaker (Hammer)

Matched precisely to the boom's capacity for optimal energy transfer.

Delivers impact energy ranging from 300 to 10,000 Joules to crush large rocks, frozen material, or boulders.

Optional nitrogen gas-assisted systems enhance impact efficiency.

3. Rotational Slewing Mechanism

Allows 360° rotation for maximum breaking coverage.

Integrated slew ring and bearing system ensures smooth, precise movement with minimal backlash.

Electric motor-driven

4. Heavy-Duty Pedestal

Designed for direct bolting onto concrete foundations or structural steel.

Provides a stable and vibration-resistant platform to withstand dynamic loads.

5. Hydraulic Power Unit (HPU)

Equipped with high-efficiency pumps, pressure regulators, and temperature controls.

Standard power range from 18 kW to 90+ kW.

HPU housed in a protective enclosure with access for maintenance.

6. Control System

Available in manual joystick, wired remote, radio remote, and 5G teleoperation system.

Joystick control allows precise manipulation of boom and hammer.

Integration with camera systems and proximity sensors enhances safety in restricted visibility zones.

Functionality & Benefits

1. Material Flow Optimization:

Prevents crusher blockages by eliminating oversized rocks before they enter the crusher chamber, reducing equipment strain and maximizing throughput.

2. Less Downtime:

Quickly deals with obstructions that traditionally require manual intervention, avoiding costly production stoppages.

3. Operator Safety:

Removes personnel from hazardous areas with remote operation options, explosion-proof electronics, and customizable interlocks.

4. Wide Application Scope:

Adaptable to primary, secondary, and tertiary crushing stations in surface mines, underground operations, recycling facilities, and tunneling projects.

Customization & Model Options

Pedestal boom rockbreaker system is available in a wide range of models to accommodate:

1. Boom Reach: From compact units for confined spaces to extended-reach models for high-wall or deep chute applications.

2. Hammer Size: Lightweight hammers for delicate work to heavyweight models for massive rock fragmentation.

3. Mounting Configuration: Stationary pedestal, wall-mounted, or mobile base designs.

4. Environment Compatibility: Designed for use in dust-laden, high-humidity, and extreme temperature conditions.

Applications

1. Grizzly Stations: Breaking large material that cannot pass through grizzly bars.

2. Jaw & Gyratory Crushers: Clearing bridging and oversized rocks at feed hoppers.

3. Ore Passes & Drawpoints: Ensuring flow continuity in underground mine ore chutes.

4. Cement & Aggregate Plants: Assisting in material sizing and flow control.

Installation & Maintenance

1. Installation

Delivered in modular form for ease of transport and rapid on-site assembly.

Engineering drawings and foundation load data provided.

Optional installation supervision and commissioning service available.

2. Maintenance

Lubrication points are centralized and easily accessible.

Predictive maintenance supported via sensor feedback (temperature, pressure, vibration).

Spare parts package includes pins, bushings, seals, and filters.

Package Inclusions

1. Pedestal boom system

2. Hydraulic power unit (HPU)

3. Hydraulic hammer

4. Embedded parts and remote control bracket

5. Installation accessories box

6. Maintenance spare parts box

7. Optional spare parts & toolbox

8. Electrical and hydraulic schematic diagram

9. Parts manual & User manual

Why Choose a Pedestal Boom Rockbreaker System?

Reliability: Built for non-stop 24/7 operation in harsh industrial settings.

Precision: Accurate control reduces over-breaking and material loss.

Efficiency: Increases crusher uptime, boosts productivity, and reduces labor costs.

Scalability: Modular and customizable to grow with your operation.

Why Choose YZH?

1. More than 20 years of production experience and rich field service experience.

2. Professional and creative R&D team.

3. ISO9001:2015, ISO14001:2015, ISO45001:2018 and CE Certification.

4. China Price&China Speed.

5. Engineered for Continuous Duty – Suitable for 24/7 mining and crushing environments.

6. Highly Customizable – Modular boom sizes, power packs, breaker options, and control types.

7. End-to-End Support – From design and manufacturing to installation, commissioning, training and after-sale service.