In the high-stakes worlds of mining, construction, and demolition, the Rockbreaker is the heartbeat of productivity. Whether you are downsizing oversized boulders in a quarry or clearing a jammed primary crusher, the right tool determines your project's timeline and profitability.

However, selecting the "right" rockbreaker is not just about picking the biggest hammer. It requires a deep understanding of impact energy, carrier compatibility, and operational safety. A mismatched unit can lead to equipment damage, safety hazards, and soaring maintenance costs.

This guide provides a structured approach to selecting the ideal rockbreaker for your specific needs.

1. Understanding the Basic Types of Rockbreakers

Before diving into specifications, it is crucial to identify which type of rockbreaker fits your application.

Hydraulic Breakers (Excavator Mounted)

These are mobile attachments connected to an excavator. They are versatile and ideal for demolition sites, road construction, and secondary breaking in the pit.

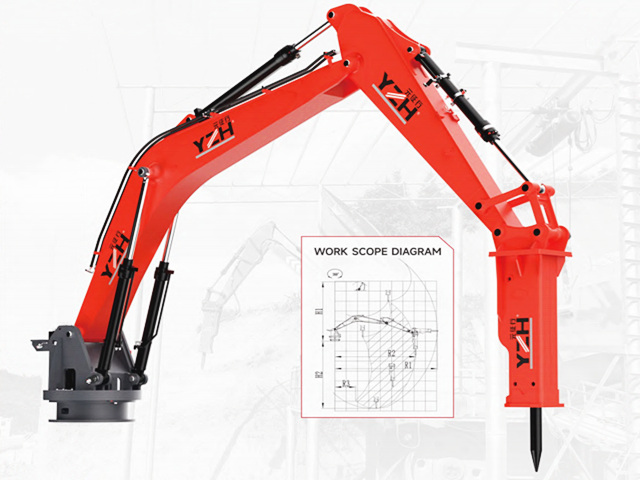

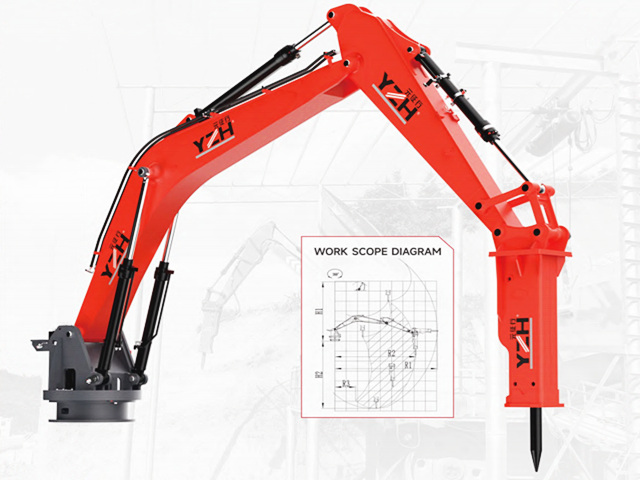

Pedestal Boom Systems (Stationary)

For quarries and mines, the Pedestal Boom System is the superior choice. Unlike mobile excavators, these are permanently mounted at the crusher or grizzly.

Pros: They are electrically powered (saving fuel), safer (remote operated), and specifically designed to clear crusher blockages without tying up a mobile excavator.

Cons: Fixed location means they cannot move around the site.

Pneumatic Breakers

Powered by compressed air, these are older technology. While simple, they generally lack the hitting power and efficiency of modern hydraulic systems.

2. Key Factors in Choosing a Rockbreaker

To ensure you get the best return on investment (ROI), evaluate these three critical factors.

A. Impact Power and Durability

Impact Energy (Joules): This is the measure of the blow force. Harder rock (like granite or basalt) requires higher impact energy. However, bigger isn't always better—excessive power can damage the carrier or the rock itself (creating too much fines).

Durability: Look for breakers made from high-tensile, wear-resistant steel (e.g., Hardox). A durable housing protects the internal mechanism from the dust and debris of the job site.

B. Compatibility

For the system to work, the breaker must match the carrier (whether it's an excavator or a stationary pedestal base).

Weight Match: The breaker must be within the carrier's lifting capacity and stability limits.

Hydraulic Flow & Pressure: The most critical technical check. The carrier's hydraulic pump must deliver the correct Liters Per Minute (LPM) and Operating Pressure (Bar). Mismatched flow results in overheating or sluggish performance.

C. Working Environment

Underground Mining: Requires compact designs and often electric-hydraulic power packs to eliminate diesel fumes.

Urban Construction: Requires noise-suppressed housings and vibration-dampened systems to meet strict city ordinances.

3. Safety Features: Protecting Your Workforce

In modern industry, safety is a non-negotiable specification. When choosing a rockbreaker, look for these advanced safety features:

Remote Control Operation: Especially for Pedestal Boom Systems, the ability to operate the boom from a safe, climate-controlled cabin via joystick or radio remote removes the operator from the danger zone (flying rock, dust, noise).

Shock Absorption: High-quality systems use vibration-dampening mounting brackets. This protects the boom structure from fatigue cracks and reduces the vibration transferred to the operator.

Auto-Stop / Blank Firing Protection: This feature stops the hammer from firing if it is not pressed firmly against the rock, preventing internal damage and extending the tool's life.

4. Cost-Benefit Analysis

The cheapest option upfront is rarely the cheapest option long-term.

Maintenance Costs: A premium rockbreaker with an automatic lubrication system and high-quality seals will have longer service intervals.

Efficiency Gains: Consider the cost of downtime. If a cheap breaker overheats every 2 hours, or if a mobile excavator takes 20 minutes to drive to a crusher jam, you are losing money. A dedicated stationary boom clears jams instantly, keeping production flowing.

Resale Value: Top-tier brands and durable equipment hold their value better on the secondary market.

Conclusion

Choosing the best rockbreaker is a balance of power, compatibility, and safety.

For general construction, a mobile hydraulic attachment is versatile. However, for mining and aggregate plants, a dedicated Pedestal Boom System offers the highest efficiency, the lowest operating cost, and the safest working environment.

Don't leave your productivity to chance. Assess your rock hardness, check your hydraulic specs, and prioritize safety features to make a choice that pays off for years to come.

FAQ (Frequently Asked Questions)

Q1: How do I determine the right size rockbreaker for my project?

A: The size depends on the hardness of the material and the size of the carrier. For stationary booms, the reach is also critical—the boom must be able to reach the entire crusher box and the feeder area.

Q2: What is the best practice for maintaining a rockbreaker?

A: The most important practice is regular greasing (every 2 hours of operation) to prevent bushing wear. Also, regularly check hydraulic hoses for leaks and ensure the nitrogen gas pressure in the accumulator is within specs.

Q3: Can I install a rockbreaker on any excavator?

A: No. You must ensure the excavator's weight class and hydraulic output (flow and pressure) match the breaker's requirements. Installing a large breaker on a small excavator can cause the machine to tip over or damage the boom.

Q4: Why choose a pedestal boom over an excavator for crusher clearing?

A: Pedestal booms are electric (cheaper energy cost), safer (remote operation), and designed specifically for the task. Excavators are expensive to run (diesel), take up space, and are often an inefficient use of a mobile asset.

Contact YZH today to discuss how we can improve safety and efficiency at your mine site.