In the mining and quarrying industries, the Rockbreaker is an indispensable tool. Whether mounted on a mobile excavator or installed as a stationary Rock Breaker Booms System over a crusher, these machines deliver immense power to fracture hard material.

However, with great power comes significant risk. Improper operation doesn't just damage the machine—it puts operators and ground personnel in immediate danger of flying debris, hydraulic injection injuries, and structural failures.

This guide outlines the essential safety protocols, operational checks, and maintenance routines required to ensure your rockbreaking operations are as safe as they are efficient.

1. Fundamental Principles of Safe Operation

Safety begins before the machine is even turned on. A disciplined approach to the "pre-start" phase is the most effective way to prevent accidents.

The Pre-Start Walkaround

Before operating any hydraulic equipment, a 360-degree inspection is mandatory.

Hydraulic Lines: Check for leaks. High-pressure hydraulic fluid can penetrate skin (injection injury), which is a medical emergency.

Mounting Hardware: Ensure all pins, retainers, and bolts are secure. A loose tool bit can become a deadly projectile.

The Work Zone: Establish a clear "Danger Zone." No personnel should be within the swing radius or the potential fly-rock zone of the breaker.

Proper Equipment Usage

Using the machine correctly is a safety feature in itself.

90-Degree Rule: Always strike the rock perpendicular to the surface. Striking at an angle causes the tool to skid, which can send rock fragments flying unpredictably.

No "Prying": Never use the breaker tool as a lever to pry rocks loose. This can snap the tool bit, sending metal shrapnel into the air.

2. Common Hazards and Prevention Strategies

Understanding the specific risks associated with rockbreaking allows you to mitigate them effectively.

Hazard A: Fly Rock (Debris)

The impact of the chisel creates high-velocity rock fragments.

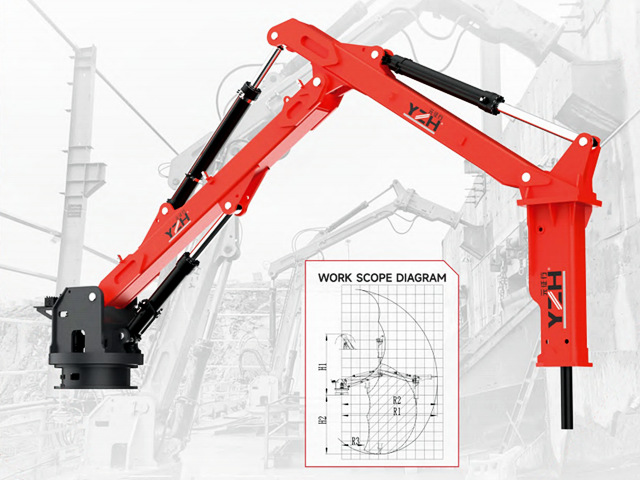

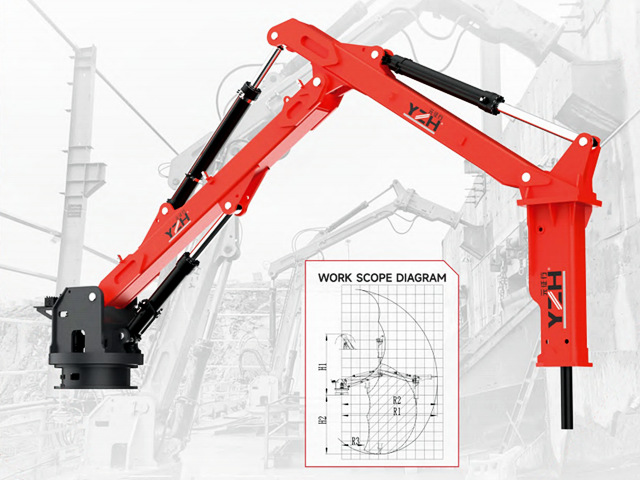

Prevention: Operators must use impact-resistant glass (cab guards). For stationary applications, installing a Rock Breaker Booms System with remote operation capabilities removes the operator from the immediate impact zone, significantly increasing safety.

Hazard B: Hydraulic Hose Failure

Sudden hose bursts can spray hot oil and cause the boom to drop unexpectedly.

Hazard C: Noise and Vibration

Long-term exposure to the percussive noise of a breaker can cause permanent hearing loss.

3. Maintenance as a Safety Protocol

A well-maintained machine is a safe machine. Neglected equipment is unpredictable and dangerous.

Critical Component Checks

Lubrication: A dry tool bushing creates excessive friction and heat, which can lead to micro-cracks in the tool steel. A sudden tool failure during operation is a major safety hazard.

Retaining Pins: These hold the heavy tool bit in place. If they are worn excessively, the tool can slide out or detach during operation.

Routine Inspections

Schedule daily checks of the Rock Breaker Booms System structure. Look for fatigue cracks in the boom arm or pedestal base. Catching a structural crack early prevents catastrophic collapse during heavy lifting.

4. Industry Standards and Regulations

Adhering to safety standards is not just about compliance; it's about survival.

ISO Standards: Modern equipment should meet ISO safety standards regarding ROPS/FOPS (Roll-Over/Falling-Object Protective Structures).

Lock-Out/Tag-Out (LOTO): When performing maintenance, the hydraulic power unit must be completely de-energized and locked out. Never service a breaker while the hydraulic system is pressurized.

Training: Only certified operators should handle these machines. "On-the-job" learning without formal safety training is a leading cause of accidents.

Conclusion

Safety in rockbreaking is not an accident; it is a choice.

By strictly following pre-start inspections, respecting the power of the hydraulic system, and utilizing purpose-built equipment like stationary Rock Breaker Booms Systems to distance operators from the danger zone, you create a culture of safety.

Remember: No production target is worth an injury. Maintain your equipment, train your team, and operate with caution.

FAQ (Frequently Asked Questions)

Q1: What is the "Danger Zone" for a rockbreaker?

A: The danger zone is typically defined as the full reach of the boom plus an additional safety buffer for flying rock. For large breakers, this can be 20-30 meters. No ground personnel should be inside this radius during operation.

Q2: How does a Pedestal Boom System improve safety?

A: A Rock Breaker Booms System is permanently mounted at the crusher. It is often operated from a remote control room equipped with cameras. This completely removes the operator from the noise, dust, and vibration of the crusher deck.

Q3: What PPE is required for rockbreaker operation?

A: At a minimum: Hard hat, safety glasses (with side shields), steel-toed boots, high-visibility vest, and hearing protection. If the operator is outside a cab, a face shield is also recommended.

Q4: What should I do if a hydraulic hose bursts?

A: Immediately hit the Emergency Stop (E-Stop) button to shut down the power unit. Do not attempt to stop the leak with your hand. Evacuate the area and wait for the system to depressurize before cleaning up.