In the demanding environments of construction, mining, and demolition, a Rockbreaker (specifically a Pedestal Boom System) is often the critical bottleneck. If the breaker stops, the crusher stops, and production hits zero.

While these machines are built for brutality, they are not indestructible. Neglecting maintenance is the fastest way to turn a profitable asset into a costly liability. A well-maintained rockbreaker not only lasts longer but delivers consistent impact energy, ensuring your operation runs smoothly.

This guide outlines the essential maintenance protocols—from daily visual checks to hydraulic system care—to help you ensure your equipment remains the "best" performer on site.

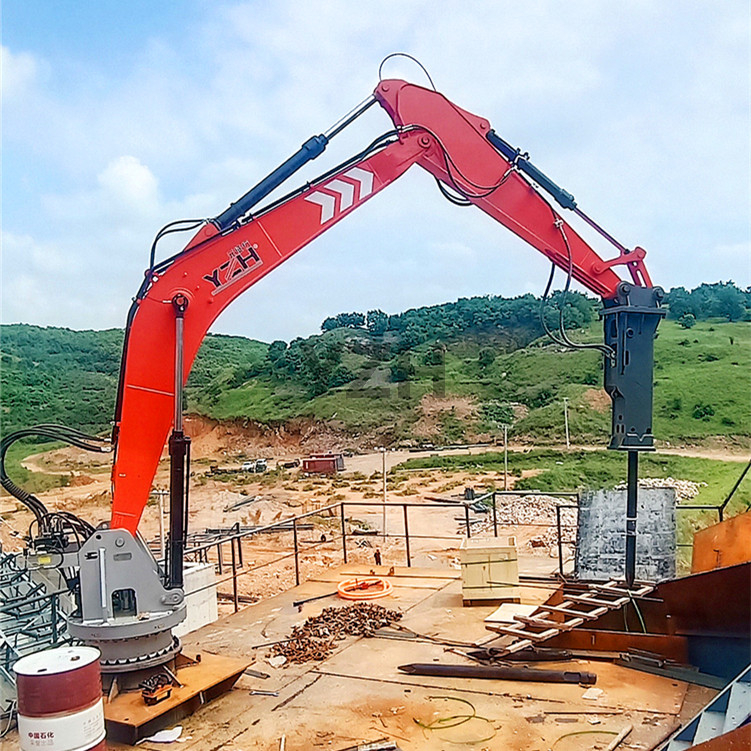

1. Understanding the Anatomy of a Rockbreaker

To maintain a machine, you must understand its components. A typical Pedestal Boom System consists of three core systems, each with specific wear points:

The Hydraulic System: The "blood" of the machine. It includes the power pack, hoses, and cylinders. Contaminated oil here can destroy the entire system.

The Hammer (Breaker): The "fist" that delivers the blow. It contains the piston, seals, and the nitrogen gas accumulator.

The Boom & Arm: The "muscle" that positions the hammer. It relies on pins and bushings to move smoothly.

The Tool (Chisel/Moil Point): The part that touches the rock. It is a consumable item subject to the most extreme wear.

2. Daily Maintenance: The First Line of Defense

Preventative maintenance starts before the machine is even turned on. A 10-minute daily routine can save thousands in repairs.

Visual Inspection

Before every shift, walk around the unit.

Check for Cracks: Inspect the boom arm welds and the breaker housing. Hairline cracks can expand quickly under vibration.

Loose Fasteners: The immense vibration of a rockbreaker can loosen bolts. Check the mounting base bolts and the tie rods on the hammer.

Hydraulic Leaks: Look for puddles of oil under the power pack or wet spots on hoses.

Lubrication: The Golden Rule

Friction is the enemy. Proper lubrication is the single most important maintenance task.

Frequency: For heavy usage, grease the tool bushings every 2-3 hours of operation.

Method: Ideally, use an Automatic Lubrication System (often available on premium Pedestal Boom Systems). If greasing manually, ensure the tool is pressed against the stop (upward) to allow grease to penetrate the impact zone.

Grease Type: Use high-temperature, molybdenum-based grease (Moly grease) designed for hydraulic breakers.

Hydraulic System Check

Oil Level: Check the sight gauge on the hydraulic tank. Low oil leads to cavitation and pump failure.

Oil Temperature: Ensure the cooling system is working. Overheated oil loses viscosity and damages seals.

3. Periodic Maintenance and Professional Inspections

Beyond daily checks, schedule these deeper inspections to catch internal issues.

Component Replacement Strategy

Bushings: The lower and upper bushings hold the tool in place. If they wear beyond the manufacturer's limit, the tool can tilt, damaging the piston. Measure wear monthly.

The Tool (Chisel): Replace the tool when the length wears down or if the tip becomes mushroomed. A dull tool transfers shock back into the machine rather than breaking the rock.

Professional 6-Month Inspection

Twice a year, have a qualified technician perform a deep dive:

Nitrogen Gas Pressure: The accumulator acts as a spring. If gas pressure is low, the breaker loses power and the hydraulic spikes increase.

Hydraulic Oil Analysis: Test the oil for metal particles (indicating pump wear) and water contamination.

Seal Kit Replacement: Depending on hours, internal seals may need proactive replacement to prevent internal bypassing.

4. Common Troubleshooting & Solutions

Even with good care, issues arise. Here are quick fixes for common symptoms:

Symptom | Possible Cause | Solution |

Low Impact Power | Low Nitrogen gas pressure | Recharge the accumulator to spec. |

Excessive Vibration | Worn bushings or loose mounting bolts | Replace bushings; torque all base bolts. |

Overheating | Clogged oil cooler or low oil level | Clean radiator fins; top up hydraulic oil. |

Leaking Oil | Damaged seals or loose hoses | Tighten connections; replace seal kit. |

5. Safety First: Operating and Maintaining Safely

Maintenance should never compromise safety.

Lock-Out / Tag-Out: Never service the boom or power pack without isolating the electrical supply.

Depressurize: Hydraulic oil is under extreme pressure. Always relieve system pressure before loosening any hoses.

PPE: Always wear eye protection, steel-toe boots, and hearing protection.

Safe Positioning: When changing the tool, ensure the boom is supported and cannot drift down unexpectedly.

Conclusion

Maintaining the best rockbreaker performance isn't a secret—it's a discipline. By adhering to a strict regimen of lubrication, visual inspection, and timely part replacement, you ensure that your Pedestal Boom System remains a profitable asset rather than a maintenance headache.

Remember: The cost of a tube of grease is pennies compared to the cost of a new piston or a day of lost production.

FAQ (Frequently Asked Questions)

Q1: How often should I grease my rockbreaker?

A: For manual greasing, it is recommended to grease the tool every 2 to 3 hours of continuous operation. If you have an automatic lubrication system, check the grease reservoir daily.

Q2: What happens if I operate the breaker with worn bushings?

A: Worn bushings allow the tool (chisel) to wobble. This misalignment can cause the piston to strike the tool at an angle, leading to permanent damage to the piston and the cylinder—the most expensive parts of the breaker.

Q3: Why is my rockbreaker overheating?

A: Overheating is often caused by low hydraulic oil levels, a blocked oil cooler (radiator), or using the wrong viscosity oil for the ambient temperature. It can also be caused by the operator "prying" with the tool, which generates excess heat.

Q4: Can I use standard chassis grease for my rockbreaker?

A: No. Standard grease melts and runs out under the high temperatures and pressure of a breaker. You must use "Chisel Paste" or Molybdenum-based grease specifically rated for hydraulic hammers (usually rated for 500°F+).