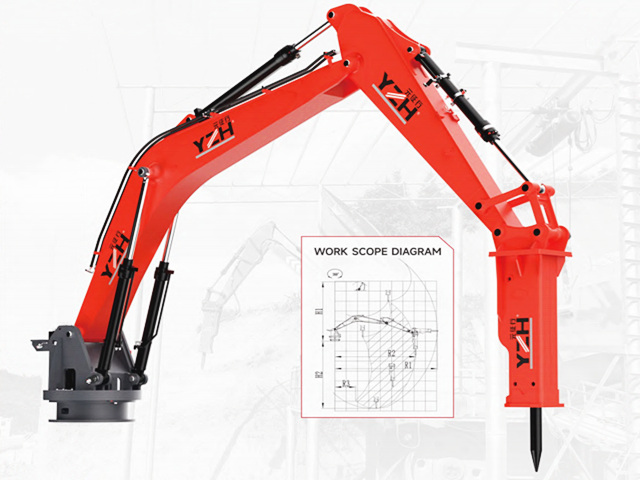

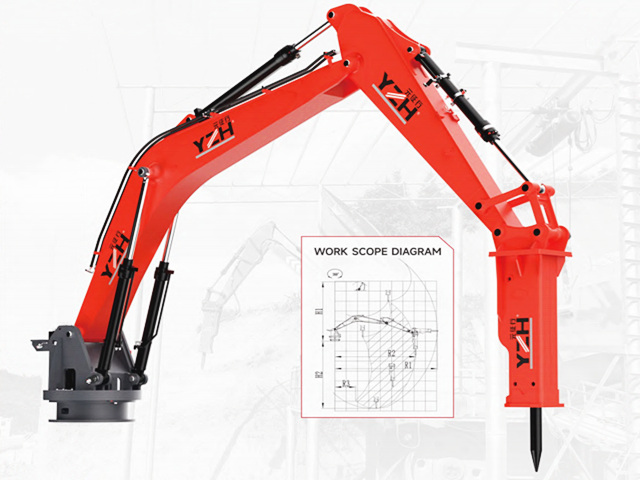

Pedestal Rock Breaker Boom System: Comprehensive Heavy-Duty Rock-breaking Solution

WH series pedestal rock breaker boom system includes: WHA460, WHA560, WHA610, WHB710, WHB810, WHC860, WHC880, WHC960, WHC970, WHC1030, WHC1030, WHC1070, WHD1000, WHD1250, WHD1350, WHE1000, WHE1500, WHEN1300, WHEN1410, WHEN1510, WHEN1850

Power of hydraulic power unit ranges: 18kw, 22kw, 30kw, 37kw, 45kw, 55kw, 75kw, 90kw, 110kw

Weight ranges: 1650kg-17040kg

Vertical reach: 1630mm-17930mm

Rotation angle: 360°

OEM/ODM: Yes

Hammer rod tool diameter: 68-175mm

Operating temperature -45°C to +75°C

Mounting options: Floor mount, Crusher mount, Shock-absorbing base, Bridge tower mount, Rail trolley mount

All systems can be tailored to site-specific conditions including high altitude, corrosive, or explosive environments.

Pedestal rock breaker boom system is a fully integrated, high-performance hydraulic rockbreaking solution tailored to meet the demands of 24/7 mining, quarrying, aggregate, recycling, and tunneling applications. Designed to ensure maximum uptime, enhanced safety, consistent material flow, and intelligent operational control, this system provides seamless rockbreaking at primary crusher inlets, grizzly feeders, dump hoppers, and material transfer points. Built with industrial-grade hydraulic, structural reinforcement, and intelligent control, our boom systems are engineered to perform in the harshest environments.

System Composition & Component Breakdown

1. Pedestal Base

Constructed from heavy-duty welded steel, the pedestal is securely anchored to a concrete or steel foundation.

It supports the full weight and dynamic movement of the boom arm and breaker, ensuring structural stability.

Vibration isolation pads may be used to reduce foundation stress and extend pedestal service life.

2. Rotary Slewing Mechanism

A high-torque slewing bearing and planetary gear reducer provide smooth 360° or limited-angle rotation, allowing optimal breaker positioning.

Slewing is powered hydraulically or electrically, depending on the model and control system.

3. Boom

Comprises multiple sections (main boom, intermediate boom, and jib stick), fabricated with high-strength steel for durability and fatigue resistance.

All joints feature reinforced pivot points with hardened pins and replaceable bushings.

Optional telescopic configurations are available for extended reach.

4. Hydraulic Breaker (Hammer)

Mounted at the end of the stick, the breaker is powered by a high-pressure hydraulic power unit.

Models range from light-duty (500–1000 joules) to ultra-heavy-duty (12,000+ joules) impact energy, suitable for various rock hardness levels.

Equipped with anti-blank firing and energy recovery systems to maximize performance.

5. Hydraulic Power Unit (HPU)

The HPU provides the energy to power the boom movements and hammer strikes.

It includes an electric motor (18–75 kW or more), oil reservoir, directional valves, filters, and cooling systems.

Flow and pressure parameters are matched to the breaker's requirements for optimal operation.

Optional features include variable displacement pumps and remote diagnostics.

6. Control System

Manual Control Panel: Operator joystick station with precise proportional control, mounted on pedestal, or in a control room or operator cabin.

2IN1 Radio Remote Control System: Wireless operation from a safe distance, ideal for hazardous zones.

5G Teleoperation Control System: Advanced AI-enabled system, enabling automated boom movement, preset positions (deploy, park), remote video monitoring, and full control over 5G or industrial wireless network.

Application & Compatibility

1. Primary Jaw Crushers

Prevents feed throat blockages caused by boulders that cannot enter the crushing chamber.

2. Gyratory Crushers

Clears bridging or oversized material stuck above the spider arm.

3. Grizzly Screens & Apron Feeders

Breaks large rocks before they enter downstream equipment.

4. Underground & Surface Mining Sites

Suitable for confined areas where mobile equipment access is limited.

5. Steel & Cement Plants

Used for slag crushing, ladle descaling, and raw material handling.

Safety & Environmental Considerations

1. Operator Safety

Designed for remote operation to keep personnel away from high-risk zones.

Boom interlocks with crusher to prevent simultaneous operation.

Emergency stop and overload protection systems integrated.

2. Environmental Durability

Corrosion-resistant coatings and weatherproof electrical enclosures.

Suitable for dusty, humid, and high-altitude environments.

Optional cold-weather packages for arctic operation down to over -50°C.

Installation & Maintenance

1. Installation

Delivered in modular form for ease of transport and rapid on-site assembly.

Engineering drawings and foundation load data provided.

Optional installation supervision and commissioning service available.

2. Maintenance

Lubrication points are centralized and easily accessible.

Predictive maintenance supported via sensor feedback (temperature, pressure, vibration).

Spare parts package includes pins, bushings, seals, and filters.

Customization Options

Boom Reach Lengths: From 3 meters to over 18 meters, depending on crusher type and site geometry.

Breaker Models: Multiple breaker sizes from top global brands (Rammer, Furukawa, Montabert, etc.).

Control Modes: Joystick, radio, or fully automated programmable control.

Power Source: Electric or diesel-powered hydraulic stations, depending on infrastructure.

Color & Branding: Custom paint and logo placement available for OEMs and dealers.

Benefits & Value Proposition

1. Maximized Uptime

Reduces crusher downtime caused by rock jams or bridging.

2. Improved Throughput

Maintains consistent feed rates and avoids production delays.

3. Enhanced Safety

Remote operation eliminates the need for manual rock removal.

4. Low Operating Cost

Reliable performance reduces maintenance frequency and energy usage.

5. High ROI

Long service life, minimal intervention, and compatibility with various crushers make it a valuable long-term investment.

Package Inclusions

1. Pedestal boom system

2. Hydraulic power unit (HPU)

3. Hydraulic hammer

4. Embedded parts and remote control bracket

5. Installation accessories box

6. Maintenance spare parts box

7. Optional spare parts & toolbox

8. Electrical and hydraulic schematic diagram

9. Parts manual & User manual

Why Choose YZH Pedestal Rock Breaker Boom System?

1. More than 20 years of production experience and rich field service experience.

2. Professional and creative R&D team.

3. ISO9001:2015, ISO14001:2015, ISO45001:2018 and CE Certification.

4. China Price&China Speed.

5. Engineered for Continuous Duty – Suitable for 24/7 mining and crushing environments.

6. Highly Customizable – Modular boom sizes, power packs, breaker options, and control types.

7. End-to-End Support – From design and manufacturing to installation, commissioning, training and after-sale service.